Abstract

This study provides an insight into the reuse of Recycled aggregate (RA), pulverized fly ash (PFA), and slag in construction. Due to the rapid increase in the construction of buildings, roads, bridges, the natural resources of the earth are significantly reducing day by day. Also, the by-products (Fly Ash) of some industries produced pollution which adversely affects our environment. Construction and demolition waste also become an Issue in Pakistan. One solution to this is to recycle these wastes and reused them in the construction industry. The recycling process not only reduced the environmental problems but will also provide sustainable development in construction. For this purpose laboratory tests were conducted on different samples (Cubes), having different mix designs of RCA, PFA, and Slag. The results show that slag has a high capacity to replace fine aggregate, while PFA has some intermediate capability of replacing cement. RCA shows poor results in replacing the coarse aggregate.

Introduction

More than some other industry, the building business is influenced by the continuous manageability face off regarding. Basically, this is because of the articulated natural effect related to the creation of building materials, the erection of structures and structures, and the resulting utilization of these structures. This is particularly valid for structures made out of cement, as the creation of this material and here particularly the generation of its crude material bond is profoundly vitality serious and causes extensive outflows of CO2.

Lessening the ecological effect amid solid creation without thinking about the effect on the execution and sturdiness of the material, be that as it may, would not get the job done, as the required lifetime of solid structures ordinarily extends between 50 to 100 years and in this manner spreads the natural effect over quite a while traverse.

Expanding the supportability of building structures in this way requires both a diminishment of the ecological effect related to the erection, upkeep, and activity forms in conjunction with an expansion of the solidness of the structure at greatest specialized execution. This can be understood by the following equation:

2.1.1 Concrete

Concrete is a mixture of Portland cement or any other hydraulic cement, fine aggregate, coarse aggregate, and water, with or without admixtures. (Institute, 14)

Concrete made from the following five components:

2.1.2 Cement and binder

Cement is the hydraulic binder (hydraulic = hardening when combined with water) which is used to produce concrete. Cement paste (cement mixed with water) sets and hardens by hydration, both in air and underwater.

2.1.3 Concrete aggregates

Concrete aggregates, consisting of sand and gravel, represent the grain skeleton of the concrete. All cavities within this skeleton have to be filled with binder paste as complete as possible.

2.1.4 Concrete admixtures

Concrete admixtures are liquids or powders which are added to the concrete during mixing in small quantities. Dosage is usually defined based on the cement content.

2.1.5 Concrete additions and supplementary cementitious materials (SCM)

Concrete additions are defined as finely divided materials used in concrete to improve or to obtain desired fresh and hardened concrete properties

2.1.6 Water

The suitability of water for concrete production depends on its origin.

2.2 Concrete Applications

Concrete is the most commonly used construction material on earth. When considered over its entire life cycle – extraction, processing, construction, operation, and demolition, and recycling – concrete make a significant contribution to the triple bottom line – environmental, social, and economic – of sustainable development.

Concrete is a versatile construction material: it is plastic and malleable when newly mixed, yet strong and durable when hardened. These qualities explain why concrete can be used to build skyscrapers, bridges, sidewalks, highways, houses, and dams.

Concrete also enables the reduction of CO2 emissions and other negative environmental impacts in many sectors.

- Homes built with insulating concrete (ICF) – reduce energy usage by 40% or more.

- Concrete buildings– last longer, reduce maintenance and energy use, and provide better indoor air quality.

- Structures made with smog-eating concrete(TX Active) stay clean and can reduce nitric oxides in the surrounding area by as much as 60%.

- Concrete highways – require less maintenance, not subject to rutting or spring thaw load restrictions, reduce fuel consumed by heavily loaded trucks.

- Agricultural waste containment – use of concrete reduces odor and prevents groundwater contamination.

- Cement-based solidification/stabilization– in situ treatment of waste for brownfield redevelopment and remediation of contaminated sites. (Anon., n.d.)

2.3 Pozzolana

Pozzolana is a globally popular word and is mostly used in construction industries nowadays. It is the most common construction material which is either natural or artificial. (Desai, 2018)

Pozzolanas contain a siliceous and aluminous mineral substance that itself possesses little or no little cementations properties. (Desai, 2018)

2.4 Slag

Slag is a byproduct of steel production and is similar in character to volcanic rocks such as basalt and granite. Slag is primarily used in the cement and construction industries, and largely in road construction. (Bauer, 2013)

A slag bond is a pressure-driven concrete shaped when granulated impact heater slag (GGBFS) is ground to appropriate fineness and is utilized to supplant a part of the Portland band. It is a recuperated mechanical result of an iron impact heater. Liquid slag redirected from the iron impact heater is quickly chilled, delivering smooth granules that yield wanted receptive cementations qualities when ground into concrete fineness.

2.5 RCA (recycled Concrete Aggregate)

The aggregate obtained from the construction and demolition waste is known as recycled concrete aggregate.

Now, British standard has also passed the usage of Recycled Aggregate Concrete and they are going to use it in their construction industry heavily.

2.6 Pulverized fly ash (PFA)

The ash obtained from different industrial emissions is known as fly ash, it can be used in the replacement of cement.

2.7 Case Study-01

It was the case study of East Midlands Airport and the fly ash was incorporated into the dry lean concrete. Compaction of the dry lean concrete (DLC) cum fly ash mix proved to be problematic due to the high fines content contributed by the combined fine aggregate. There was no need of using the agitator paddles in the truck bodies with the DLC due to the free-flowing nature of the fly ash mix. The desired criteria for the cured beams was to gain a strength of 6.3 MPa at 28 days in the laboratory and the average strength achieved for the contract was 6.9 MPa at 28 days. The extended setting times of pulverized fly ash (PFA) in pavement quality concrete (QPC) allow the concrete to be properly compacted and finished without problems even on the hottest days. During placing or compacting, excellent surface finishes are observed with no bleeding or segregation of the concrete mix and thermal movements, and the risk of cracking is also greatly reduced. No cracking except at sawn joints has been taken place as the strength is gained at a slower rate in the early ages. The strength gained by fly ash after 28 days results in stronger and more durable concrete for the long term. PFA can produce economical concrete. The use of 30% PFA in concrete mixes can reduce greenhouse gas emissions by 17% and energy use by 14%. (Association, 1999)

2.8 Case Study-02

It was the case study of Bar End Winchester for the use of recycled and secondary aggregate in the construction of a household waste recycling center and access road. The demolition waste and asphalt from the existing building were already on-site, thus the crushing and grading were carried out on-site using a mobile crushing plant. The use of recycled aggregates and recycled asphalt in the sub-base and earthworks was easier to lay than the equivalent primary materials. The materials performed very well, they met all specification and quality requirements and were easy to handle and compact. The technical benefits of using incinerator bottom ash (IBA) in foamix (a blend of carefully combined ingredients bound together by a ‘foam’ of bitumen and water) as being an easy material to handle which is very consistent in its properties. The recycled aggregates used were from the demolition of the buildings and the existing access road on the site, thus the project was cost-effective. No landfill tax or aggregates levy charges were paid as all the onsite available materials were reused and all the imported materials were recycled or secondary aggregates, thus the transport cost of bringing primary aggregates onto the site was saved money. The crushing machine was also brought once onto the site, which made the project inexpensive. The use of the recycled materials saved money in the sub-base and capping layers. There were some marginal additional costs in producing the concrete due to design trials and the additional material handling required for blending the recycled coarse aggregate (RCA) with the other coarse aggregates, resulted in the use of the demolition material on site so less waste was generated. The project required a lot fewer lorry movements than if all of the demolition materials had needed to be taken away and new primary aggregates had to be brought onto the site. (Council, 2004)

Aims and Objective of the Report:

The key report in this report is the development of concretes with minimum environmental impact lies in maintaining sufficient workability of the concrete at very low water contents.

As in the fresh state, water is needed to fill the inter-granular voids in the mix consisting of aggregates and cement particles, and to lubricate the deformation of this granular system, a reduction of the water content at constant packing density would inevitably result in a loss of workability and the formation of voids.

The use of fly ash in Portland cement concrete (PCC) has many benefits and improves concrete performance in both the fresh and hardened state. The benefits are the following:

- Improved durability

- Increased ultimate strength

- Improved workability

- Reduced permeability

- To prepare such green concretes that may possess a very good performance when they are composed according to the mix design procedure.

- To serve as the leading source of knowledge for slag cement and slag blended cement through promotion, education, and technology development. To communicate the performance and environmental benefits of these cementations materials through the support and participation of member companies.

2.9 Methodology

First of all the concrete cubes are made in a concrete laboratory keeping in mind the specification of the cube. Safety is considered first in making the cubes in the laboratory. A slump test is performed first to check whether the concrete is usable or not.

Different cubes are formed of a different mix of PFA, RCA, and Slag. Proper compaction is done during cube making. The cubes are then properly labeled. Curing is done properly for each type of cube.

The cubes are then tested in the UTM laboratory for compressive tests. The compressive tests are done for 7, 28, and 90 days for each type of cubes.

The results are noted in the excel sheet for further processing and calculations.

3 Results and Calculations

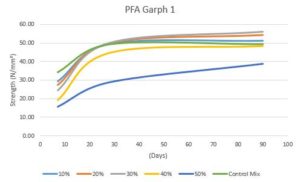

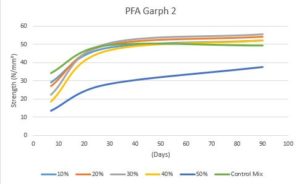

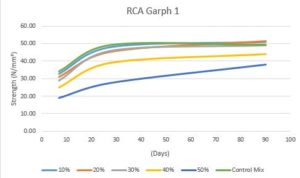

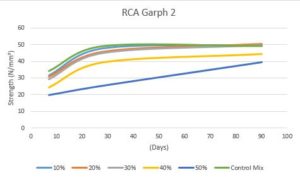

The results obtained from the tests are then analyzed in Microsoft excel after analysis and calculations the results are then tabulated and plotted. Table 1, is related to the pulverized fly ash, Table 2 is concerned with the recycled concrete aggregate, and Table 3 shows the values of slag as given in Appendix.

Also, graphs are plotted for PFA, RCA, and slag as shown in the appendix.

4 Discussion

4.1 PFA:

The results obtained for replacements of cement by ash shows that when we replaced 10% cement with fly ash then initially for 20 days its strength is slightly lesser than the control mix, but the results obtained for 90 days indicate that its strength is higher than the control mix. Similar results are obtained from 20 and 30 % replacement. But as the %age of fly Ash is increased above 30% then it’s considerably reduced, while above 50% replacement of fly ash gives us very lower strength.

10% replacement gives us a somewhat similar result to the control mix. Keep in mind the values of tests, the acceptable and optimum value is 30% replacement of cement by fly ash. So 30% is the intended mix design as it has high compressive strength as compared to other mix designs.

4.2 RCA

The results of the tests obtained from the samples of the recycled concrete aggregate (RCA) show poor results compare to the control mix. 10% replacement of RCA aggregate gave us somewhat the same results as that of control mix design. The poor values of 20% and above shows that this mix should not be used in the construction industry and would be avoided. So 10% replacement of RCA is the best and intended mix design for its acceptable values.

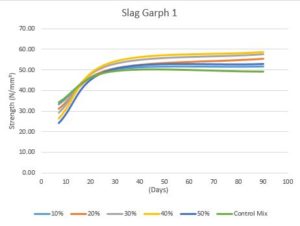

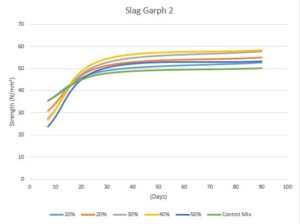

4.3 Slag

The replacement of slag shows better results as compared to PFA and RCA replacement, from 10% to 40% there is a gradual increase of compressive strength, but 50% replacement gave significantly lesser value as compared to 40% of replacement. So 40% replacement is the intended mix design of slag.

5 Conclusion

10 to 30% replacement of fly ash gave a better result than the control mix, while greater than 30% replacement of fly ash gave the poor result, so 10 to 30 % replacement of fly ash is recommended for construction.

40 % slag replacement is the optimum level at which the concrete mix gave us the better result as compared to the control mix, so therefore 40% replacement of slag is good for high strength.

Recycled concrete aggregate shows the poor result as compared to normal aggregate, so the replacement of RCA is not recommended.

Finally, 30% replacement of cement by fly ash, 10% replacement of aggregate by RCA, and 40% replacement of fine aggregate by Slag is the most suitable mix design.

Recycled concrete aggregate was not significantly detrimental to strength, particularly when the concrete also contained slag. Hence, it was possible to produce concrete with a target 28-day compressive strength of 40 MPa suitable for many structural applications, including wind turbine foundations. The coefficient of permeability and chloride diffusion coefficient was increased to a small degree by fly ash or recycled concrete aggregate, although the values remained satisfactory for durable concrete.

Elastic modulus was decreased when either fly ash or recycled concrete aggregate was incorporated in concrete. There appeared to be some incompatibility or possible contamination issues with the fly ash used in the research project which resulted in relatively poor performance of the mixes with 50% fly ash.

This finding demonstrated that it cannot be assumed that all sources of fly ash will necessarily improve the properties of concrete at high replacement levels and that detailed testing of specific materials and mix proportions is recommended before use in construction projects.

6.References

Anon., n.d. concretesask. [Online]

Available at: http://www.concretesask.org/resources/concrete-applications

Association, U. K. Q. A., 1999. The United Kingdom Quality Ash Association. [Online]

Available at: www.ukqaa.org.uk/wp-content/uploads/2014/02/Case_Study_2_Apr_2004.pdf

Bauer, S., 2013. voestalpine. [Online]

Available at: www.voestalpine.com/blog/en/general-en/slag/

Council, H. C., 2004. Wrap. [Online]

Available at: www.wrap.org.uk/sites/files/wrap/Recycled_and_secondary_aggregate_use_in_the_construction_of_a_Household_Waste_Recycling_Centre_and_Access_Road_at_Bar_End_Winchester.PDF

Desai, K. M., 2018. quora. [Online]

Available at: www.quora.com/What-is-Pozzolana

Institute, T. A. C., 14. ACI 318. s.l.: The American Concrete Institute.

Berndt, Marita. (2018). SUSTAINABLE CONCRETE FOR WIND TURBINE FOUNDATIONS. 10.2172/15008841.

Fly Ash Facts for Highway Engineers, Retrieved from https://www.fhwa.dot.gov/pavement/recycling/fach03.cfm

7.Appendix

Table 1 Pulverized Fly Ash (PFA) Mix Properties

| 10% | 20% | 30% | 40% | 50% | Control Mix | |

| (Days) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) |

| 7 | 29.35 | 27.34 | 24.39 | 19.15 | 15.57 | 34.2 |

| 7 | 29.13 | 27.15 | 22.34 | 18.75 | 13.57 | 34.2 |

| 28 | 49.33 | 49.98 | 49.99 | 44.57 | 28.79 | 49.2 |

| 28 | 47.67 | 49.18 | 50.07 | 45.98 | 27.82 | 49.2 |

| 90 | 51.07 | 54.38 | 55.99 | 48.24 | 38.76 | 49.26 |

| 90 | 52.04 | 54.03 | 55.64 | 51.99 | 37.69 | 49.26 |

Table 2 Recycled Concrete Aggregate Mix Properties

| 10% | 20% | 30% | 40% | 50% | Control Mix | |

| (Days) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) |

| 7 | 32.74 | 31.08 | 28.93 | 24.93 | 18.99 | 34.2 |

| 7 | 31.51 | 30.57 | 29.23 | 24.26 | 19.81 | 34.2 |

| 28 | 48.18 | 45.38 | 45.89 | 38.99 | 27.69 | 49.2 |

| 28 | 47.62 | 45.79 | 44.89 | 39.48 | 25.39 | 49.2 |

| 90 | 51.08 | 51.35 | 48.94 | 43.9 | 38.21 | 49.26 |

| 90 | 49.75 | 50.6 | 49.56 | 44.56 | 39.47 | 49.26 |

| 10% | 20% | 30% | 40% | 50% | Control Mix | |

| (Days) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) | Strength (N/mm²) |

| 7 | 33.40 | 31.28 | 29.33 | 26.28 | 24.28 | 34.2 |

| 7 | 35.4 | 30.84 | 27.28 | 26.7 | 23.71 | 35.4 |

| 28 | 49.73 | 50.28 | 52.34 | 53.38 | 49.97 | 49.2 |

| 28 | 48.67 | 50.89 | 52.17 | 53.77 | 49.85 | 47.48 |

| 90 | 51.57 | 55.38 | 57.49 | 58.56 | 52.87 | 49.26 |

| 90 | 52.64 | 55.04 | 57.82 | 58.32 | 53.36 | 50.09 |

Figure 1: Comparative graphs of a different mix. Of Pulverized fly ash replacement and Control MIx-1

Figure 2 Comparative graphs of a different mix. Of Pulverized fly ash replacement and Control MIx-2

Figure 3 Comparative graphs of a different mix. Of Recycled concrete aggregate replacement and Control MIx-1

Figure 4 Comparative graphs of a different mix. Of Recycled concrete aggregate replacement and Control MIx-2

Figure 5 Comparative graphs of a different mix. Of Slag replacement and Control MIx-1

Figure – Comparative graphs of a different mix. Of Slag replacement and Control MIx-2

Experimental Work: