Executive Summary

This report presents a thorough research on I-35 bridge collapse in Minneapolis in 2007. The 1,907-foot-long, eight-lane I-35W Highway Bridge that was constructed over the Mississippi River in Minneapolis, Minnesota, meet a disastrous breakdown in the core span of the deck truss. The major cost of the failure was the loss of lives of 13 people who died in the incident along with 145 people injured. The second major cost of failure was the inconvenience caused to the citizens and the third cost of failure to the economy was approximately half a billion dollars.

Since its opening in 1967 to the day of the collapse, the I-35W Bridge experienced three major renovation or modification projects. The National Transportation Safety Board (NTSB) carried out a comprehensive investigation after the collapse and discovers the following safety issues in their investigation:

- Unsatisfactory bridge design, poor quality control procedures for designing bridges, and inadequate Federal and State procedures for reviewing and approving bridge design plans and calculations.

- Lack of guidance for bridge owners regarding the position of construction loads on bridges during maintenance or repair activities.

- Lacks of inspection supervision for conditions of gusset plate bend.

- Elimination of gusset plates in bridge load rating guidance.

- Scarce utilization of technologies for correctly evaluating the condition of gusset plates on deck truss bridges.

Lastly, the report presents an extensive number of suggestions that it had implemented before could have prevented the failure.

Introduction:

Bridges of United States are facing some severe structural failures over the past years. According to expert engineers around 8000 bridges in the United States requires immediate remodeling to avoid future accidents or damages. 2007 marks a year when three main bridges collapse in the U.S. These were:

- Harp Road Bridge in Greys Harbor County, WA

- MacArthur Maze in Oakland, CA

- I-35 collapse in Minneapolis, MN

Among these, I-35 collapse in Minneapolis was the major one because it was only fatal and the most expensive among the three bridges. Before its collapse, the bridge was assessed by US regulatory agencies and was considered as a poor structure that raises questions on the state repairs and maintenance measures.

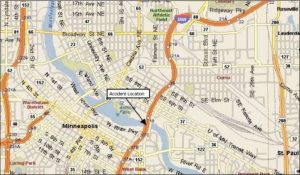

Incident: I-35 collapse in Minneapolis

The incident took place on Wednesday, August 1, 2007, at around 6:05 p.m. central daylight time. The 1,907-foot-long, eight-lane I-35W Highway Bridge that was constructed over the Mississippi River in Minneapolis, Minnesota, meet a disastrous breakdown in the core span of the deck truss. Because of which 1,000 feet of the deck truss collapsed, followed by around 456 feet of the major span falling from 108 feet into the 15-foot deep river. The bridge was the southeastern border of the Mississippi Mile downtown riverfront parkland. This bridge connects the Minneapolis regions of Marcy-Holmes and Downtown East. (NTSB, 2007)

Cost of the failure:

The major cost of the failure was the loss of lives of 13 people who died in the incident along with 145 people injured. At the time of the incident, 111 vehicles were present on the collapsing part of the bridge. Among these vehicles, just 17 were recovered from the water.

The second major cost of failure was the inconvenience caused to the citizens for whom this bridge was the main transportation route of the region. According to an estimate in 2004 above 140,000 vehicles use to cross the bridge on daily basis.

The projected cost of failure to the economy was $60 million. It took 414 days for the replacement of the bridge after the collapse to the reopening on September 18, 2008, with $234 million as the cost of replacing the bridge. As the loss of the bridge cause the commuting problem that too directly impacted the Material or Labor Costs; hence, an additional $400,000 per day was spent as commuting costs making a grand total of approximately half a billion dollars.

The Maintenance and Monitoring Routines for the bridge prior to its failure:

I-35W Highway Bridge, officially designated as Bridge 9340, was designed by Sverdrup & Parcel according to the standard specifications of 1961 AASHO (American Association of State Highway Officials). At that time, the construction contracts of the bridge were worth above US$5.2 million and were given to Hurcon Inc. and Industrial Construction Company that built the steel trusses and deck. The construction of the bridge started in 1964 and it took three years to complete the structure of the bridge. The bridge was opened to traffic in 1967. The bridge was 1,907 feet long and holds eight lanes of traffic, four southbound and four northbound. More than 141,000 vehicles cross the bridge per day, with an average of 5,640 heavy commercial vehicles.

Since its opening in 1967 to the day of the collapse, the I-35W Bridge experienced three major renovation or modification projects. These were:

1977 Renovation:

In 1977, it was found that the life of the bridge is decreased life because of rebar corrosion from the rebar interacting with road chemicals. The suggested way out was to enlarge the concrete overlay to shield the rebar. Hence, the renovation in 1977 includes the task of increasing the bridge’s deck thickness by milling the bridge deck surface to a depth of 1/4 inch and adding up a wearing course of 2 inches of low-slump concrete.

1998 Renovation:

This renovation includes the replacement of Median Barrier, improving drainage, upgrading outside concrete Traffic Railings, retrofitting cross girders, replacing bolts, repairing the concrete slab and piers and installing an Anti-Icing System.

2007 Repair and Renovation:

At the time of the collapse, Repaving Roadway work was in progress on the I-35W Bridge. The renovation task was assigned to the Progressive Contractors, Inc. (PCI), of St. Michael, Minnesota and was responsible for removing the concrete wearing track to a depth of 2 inches and replacing it with a new 2-inch thick concrete overlay. In addition, the renovation plan includes the removal of unsafe concrete from the curb and patching it with concrete, reconstruction of the expansion joints, and eliminating and restoring the anti-icing system spray disks and sensors in the deck. The project starts in June 2007 and had a planned considerable completion date of September 21, 2007, with final completion anticipated by October 26, 2007. PCI had already completed seven concrete section overlays and was about to set up the eighth section overlay at the time when the bridge collapsed.

An investigation that took place post-failure

The National Transportation Safety Board (NTSB) carried out a comprehensive investigation after the collapse. The Federal Highway Administration (FHWA) too inspects the incident, by making a replicated model of the bridge and attaches that mean as the component of the analytical process. The FHWA recommends states to examine 700 bridge of similar structure after its investigation. (WALD, 2008)

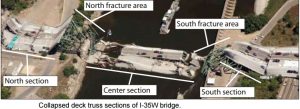

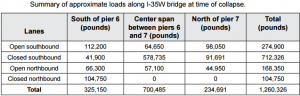

The investigation of the failure begins with analyzing the basic structure of the bridge. The bridge structure used welded built-up steel beams for girders and truss members, through engrossed and secure connections. The bridge consists of 13 unbreakable concrete piers and 14 spans. The moment the bridge collapse, the deck truss part divides into three large sections. Majority comprises of the central span, with the deck truss between piers 6 and 7 alienated from the rest of the truss and fell into the river. The division south of pier 6 fell on land on the south region of the river, while the section north of pier 7 fell on land on the north area of the river as shown in the picture below:

The road renovation work on the I-35W Bridge was in progress on the day of the collapse with four of the eight travel lanes (two inside lanes southbound and two outside lanes northbound) were closed to traffic. Construction aggregates (for concrete production_sand and gravel) and

construction tools were brought and placed in the two closed inside southbound lanes in the early afternoon. The aggregates and equipment brought for the placement of concrete on the southbound lanes were ready by around 2:30 p.m. and was planned to site around 7:00 p.m. and were therefore placed near the south end of the center part of the deck truss section of the bridge. (News, 2008)

The post-failure investigation by National Transportation Safety Board finds that the main reason behind the collapse of the I-35W Bridge in Minneapolis, Minnesota was the gusset plate that was cracked due to the inadequate load capacity. They consider it a design error by Sverdrup & Parcel and Associates, Inc., of the gusset plates at the U10 nodes that botched with the combination of an extensive increase in the weight of the bridge.

At the same time, if we look at the other side, though the load capability was an issue, yet a very heavy load too had to be positioned on the bridge to provide an adequate amount of pressure to fracture it. Gusset plates play an important role in the structural integrity of any bridge as they support the joints of the bridge. Usually, they are strong enough to sustain the whole bridge for more than 50 years. Hence, the investigation searched on what makes this gusset plate fracture and finds out that these gusset plates had insufficient load capacity.

The above image demonstrates a fracture in a gusset plate which was the main reason in the collapse of the Interstate 35W Bridge. While the below image shows the location of the gusset plate and how it looks like when it’s all right.

Hence the tracking chart for the collapse is as follows:

In this regard, there were two main reasons that contribute to the bridge to collapse.

- First was the increased dead load associated with the construction work on the bridge along with the high volume of traffic on the bridge. It was the rush hour of the day and as half of the lanes were closed, the bridge was doubled in use since the time it was built. According to the document records, the delivered weights for the aggregates placed on the bridge were 198,820 pounds of sand and 184,380 pounds of gravel, making a total weight of 383,200 pounds. The projected weight of the construction vehicles being parked on the bridge, equipment, and workers in the region was 195,535 pounds, making an overall projected weight of 578,735 pounds placed on the inner west part of the bridge center span just north of pier 6. (Lijesen & Shestalova, 2007)

- According to the US Federal Government Rating, the second factor that leads to the accident was a deficiency in the initial structure of the I-35 Bridge. Because when they investigate that why was the load capacity of the gusset plate inadequate; they found that the design thickness of the gusset plate was unsatisfactory, as is proof by its half-inch thickness instead of the standard 1 inch. The design fault was the failure of Sverdrup & Parcel’s quality control measures to make sure that the correct main truss gusset plate computations were carried out for the I-35W Bridge and the insufficient design evaluation is done by Federal and State transportation officials. The company’s own design evaluation process was not followed as there was no course of action for making sure that all calculation had been performed. Besides, the common conventional practice among Federal and State transportation officials of paying not enough concentration to gusset plates during inspections for the setting of distortion, for instance, bowing, and of not including gusset plates in load rating investigation. Lastly, there was no supervision from the government that makes the fault went overlooked, leaving the bridge a 40-year window of chance to collapse. (Petrány, 2013).

Have you read this:

Root Cause of the Collapse:

Generally, Gusset plates are not believed as a critical part with respect to load rating and in this case, were barred to make the overall analysis simplified. For some reasons, this point can be justified because gusset plates are generally presumed to be stronger than the parts they connect and somewhat this supposition is right. However, in I-35W Bridge case, the gusset plates were not suitably sized, consequently compromising the potency of the bridge. Secondly, this deficiency in the design remained unnoticed till the day of the bridge collapse.

Further investigation presumed that the gusset plates were displaced (bowed) during the course of construction and this thing remains unspecified. Gusset plates can be damaging to the structure of the bridge as they are the joints that support the other parts of the bridge. Additionally, these gusset plates were not even listed as separate inspection components along with workers having no training on gusset plate inspection. (Stawicki, 2007)

After I-35 Bridge tragic collapse, improvements were made to avoid the possibility of any future collapses of this kind. The repercussion research has provided the construction teams numerous prevention strategies in order to circumvent any future damage that might happen as fallout from such a collapse. (Minnesota, 2014)

Suggestions for an Asset (Bridge) Management System

The following list presents some suggestions that it had implemented before could have prevented the failure.

- Firstly, two kinds of inspection could have resolved the problem; first is the general bridge inspections and second is the load rating inspections as it determines the maximum limit of weight a bridge can carry.

- Secondly, the construction contractor should have an eye on the amount of Weight of Construction Materials placed on the bridge. If the contractor had this attentiveness, the collapse may have been prevented.

- Thirdly, there should be a rule of having a written Permission letter from the government or the contracting entity of placing the Construction Materials on Bridges. If the construction contractor would have bound for the requirement of permission, he would never have placed this much weight on the bridge and could possibly have prevented the concentration of weight on the gusset plate.

- Fourthly, the contracting entity should have ensured that the Bridge Construction Inspectors had received all the Bridge Instruction Training before handing over the duty.

The same people who gave supervision for bridge training were assigned the task of inspecting the bridge afterward. Cross training of the instructors would allow them to review the state of the bridge. - Another suggestion is that the team should have rechecked weight analyses after dead weight increases. Verification subsequent to the rise in the dead weight of the bridge would have presented a more rational understanding of the bridge’s load capacity.

- A further suggestion includes adding gusset plates as a part of design review. Through this action, the gusset plates could have been double checked.

- Furthermore, making the checklist of all calculations and performance measures would have ensured that the design evaluation process was followed up.

- Additionally, instead of relying on the presumed strength of the gusset plates, the team should have carried out a thorough analysis of the strength and capacity of each and every part of the bridge and specifically of gusset plates might have tipped off officials to possible problems.

- Lastly, providing education on the significance of Gusset Plates as part of the load rating, on the properly sized and strength of the plates; and in this regard providing specific training on Gusset Plate Inspections that includes the process of designing, building and examining the bridge.

Bibliography

Lijesen, M. & Shestalova, V., 2007. Public and private roles in road infrastructure: an exploration of market failure, public instruments, and government failure, s.l.: CPB Economic policy analysis.

Minnesota, C., 2014. Friday Marks 7 Years Since I-35W Bridge Collapse. CBS Minnesota, 2 August.

News, C., 2008. NTSB: Design flaw led to Minnesota bridge collapse. CNN NEWS, 15 November.

NTSB, 2007. A collapse of I-35W Highway Bridge Minneapolis, Minnesota August 1, 2007, Washington, D.C.: National Transportation Safety Board.

Petrány, M., 2013. The Ten Greatest Infrastructure Failures In Modern History. Jalopnik, 13 August.

Stawicki, E., 2007. Why did the bridge collapse?. MPR News, 2 August.

WALD, M. L., 2008. Faulty Design Led to Minnesota Bridge Collapse, Inquiry Finds. The New York Times, 10 January.